machines are our passioN

Your premium partner for high volume output.

LANTZTECH engineers and manufactures industrial machines and equipment for high-volume production, primarily serving the automotive sector. Everything is built in-house, utilizing our own CNC machining for component production, incorporating quality hardware, and integrating our own in-house developed control system.

Lantztech Machines

Open & closed head crimpers

LANTZTECH’s open and closed head crimping machines are engineered to handle high-volume demand with unmatched consistency. They ensure strong, repeatable crimps on automotive hoses and tubes.

Leak & Pressure Testing Systems

Designed to validate assembly under rigorous conditions, these leak and pressure testing machines ensure every automotive hose and tube meets quality standards – ideal for automotive safety and performance assurance.

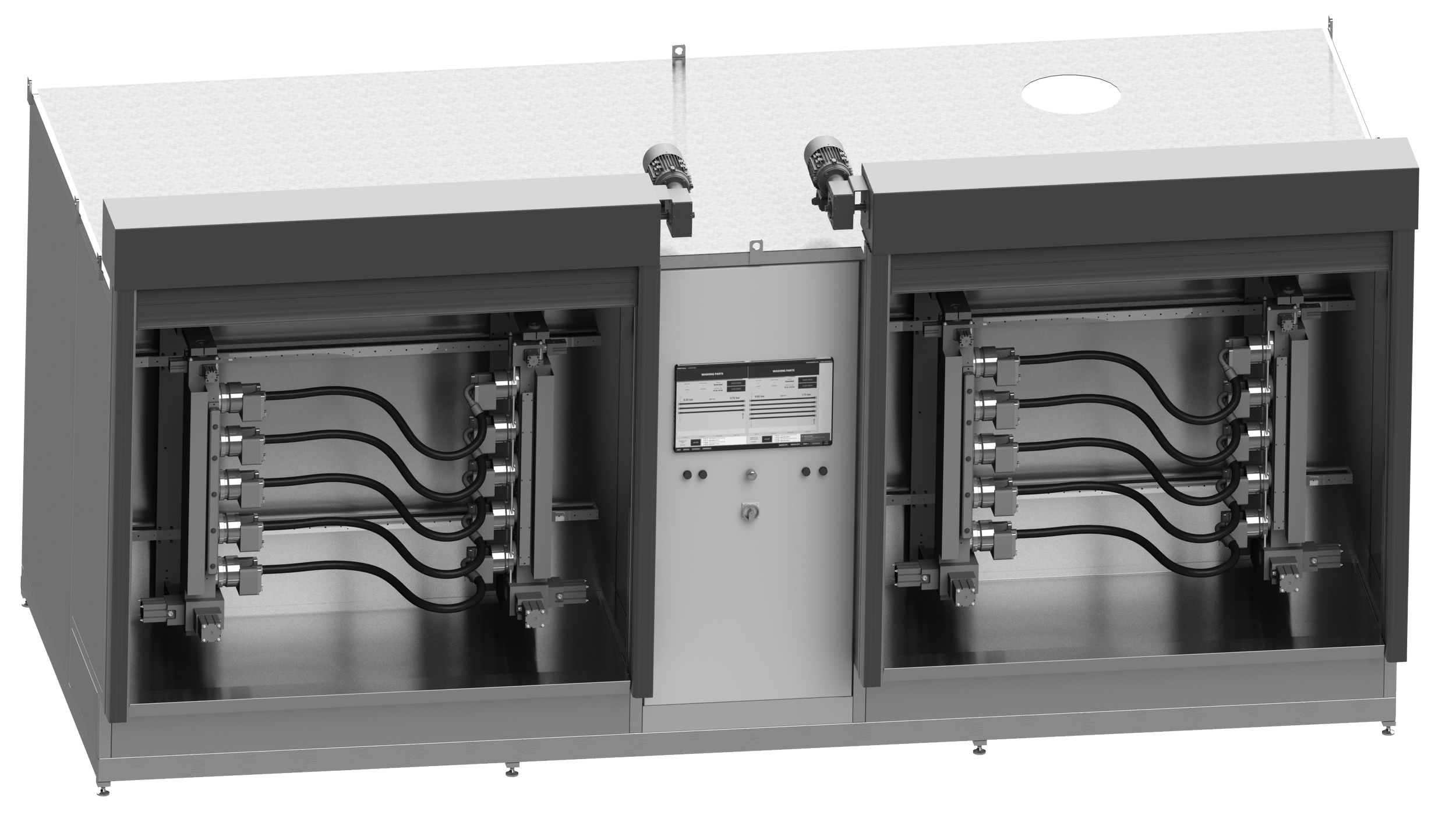

Flushing machines

Our flushing machines offer high-performance liquid cleaning of hoses and tubes, as well as flow/pressure testing, and dry-air blowing. Capable of handling production demands up to 4 000 bar. Ideal for ensuring cleanliness of hoses and tubes.

Assembly machines

Automating intricate assembly tasks, these systems enhance efficiency, reduce cycle times, and maintain precision—perfectly suited for high-volume production lines.

Hose cutting machines

A range of automatic hose cutting machines designed for high-volume production. Models like the CM‑6000‑10 support dual bobbins, automatic measuring and length cutting up to Ø2″, color marking, inkjet printing, and bundling – all controlled via ARC for seamless operation and traceability.

Quality control machines

A versatile range of in-line quality control machines designed to ensure production reliability in high-volume environments. These machines are tailored to the client’s quality requirements.

Vision & 3D Scanning

Advanced vision and 3D scanning systems that integrate into automated cells or operate standalone. The DIMENSION 2 provides rapid 2D measurement, while the DIMENSION 3 delivers full 360° 3D scans for tight tolerance verification.

Customized machines

Fully custom-engineered machines – such as the APTO 3000‑VI with laser scanning, SCARA robots, shuttles and index tables, or the APTO 7000‑EL for trimming, pressing, weighing, and sorting molded rubber parts – built collaboratively with clients to tackle unique production challenges and supported remotely via ARC Control System.